It has been the real time experience of the electronic equipment manufacturers that it is more advantageous to work with a single PCB fabrication and PCB assembly company on a long-term basis instead of changing their manufacturers frequently. This however does not mean that you have to be stuck with a single supplier all your life. There are times sticking to the same supplier could prove to be detrimental to the growth of your company. Here are a few important signs or indicators that tell you it is probably time to look for an alternative supplier of PCBs.

Initially when you were searching for your PCB fabricationcompany you may not have had adequate experience in selecting the right suppliers. You could have even approached an intermediary or a supplier that does not own their manufacturing facility. Such suppliers would be sourcing on your behalf and sending you the required PCBs through a third-party manufacturer. This has a number of disadvantages as you could easily notice now after a few years of experience in the field. Firstly, you are likely to spend more money when you do not deal directly with a manufacturer. Your supplier or intermediary is likely to markup the price and also get a commission on both sides for their service. This will unnecessarily pump up the price. Such suppliers will not have any control over the quality of the PCBs they deliver to you and also any control over the deadlines committed. In other words, there will always be a confusion in processing your orders. There is no need to go through all these and it is best to look for a different supplier with their own manufacturing facility.

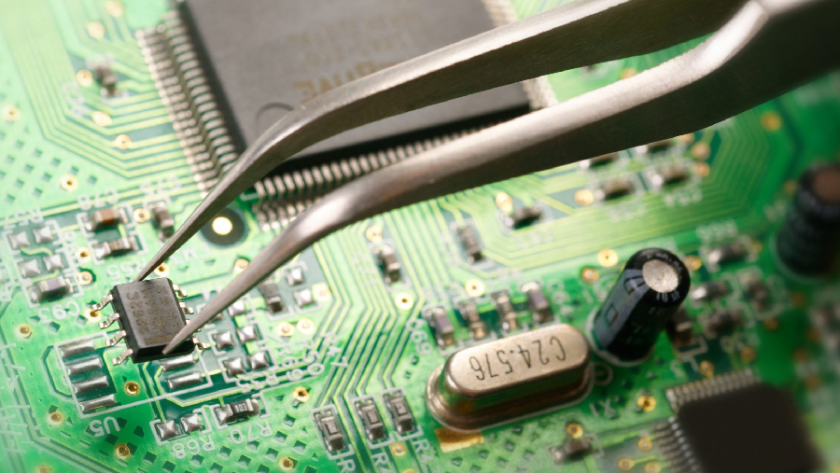

The second indicator that you should be alert about is the deterioration in the quality of the PCBs delivered. If your manufacturer is not delivering you consistently good quality PCBs then you should not delay any further in changing them. The quality of the PCB that sits in your devices will decide the quality of your products. If the PCBs are of inferior quality so will be your products. Therefore, do not hesitate in this case because it is your brand reputation that is at stake here. This often happens as you age with your supplier. Initially to impress the new customer they will deliver excellent quality PCBs and once they have earned their trust and once, they settle with their suppliers they will not focus on the quality of the PCBs supplied. Once you start noticing such changes then you could bring it up with your manufacturer and if they continue with the same fashion then do not hesitate to make the required changes.

Thirdly, issues with the timeliness of the orders delivered could be a very important indicator. If there are issues with the delivery of the orders then there could be many problems in your own production cycle. Instead of dealing with all those challenges you need to look for a better supplier.

ChinaPCBOne Technology LTD. is the author of this article on PCB assembly. Find more information, about PCB fabrication.